Classical V-Belts

Classical V-belts are the most common belts used in various applications, including ventilation, agriculture, industrial machinery, etc. Classical V-belts are less efficient than narrow V-belts and generally promote higher bearing loads. However, classical V-belts have a high tolerance for poor operating conditions.

HVH Industrial works with manufacturers' specialized engineering teams to meet our customers' requirements and highest quality standards.

If you have any questions write us via live chat, (one of our team members will answer your questions), give us a call or send us a quote request. The HVH team is always ready to help you.

1(866)577-4040

1(866)577-4040

or

Manufacturers

Classical V-Belts

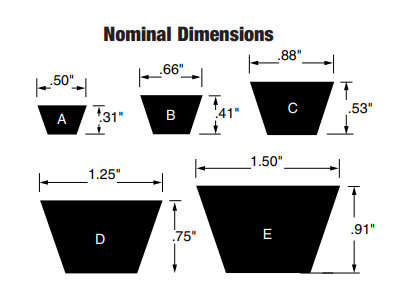

Classical V-Belts are the most common and economical belts in the industry. The width ranges from 1/2" up to 1-1/2" and lengths from 16" up to 400". Nominal dimensions for A, B, C, D, and E types are as described in the picture below.

Bias cut, rubber-impregnated fabric cover provides superior flexibility and friction resistance. Oil and heat resistant. Ultra high-strength polyester cords assure fatigue resistance and length stability while providing the flexibility needed to attain long, trouble-free service.

Classical Cogged V-Belts

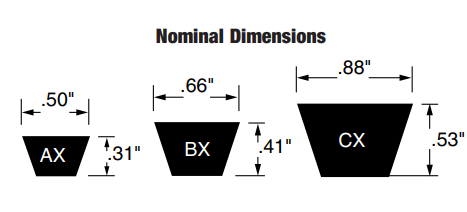

Research shows that using Cogged V-belts can save you tons of money on energy consumption. The precision molded raw edge cogged construction transfers power with much greater efficiency, allowing for smaller sheave sizes and increased power transmission capabilities. Nominal dimensions for AX, BX, and CX types are as described in the picture below.

The bias-cut cover stock provides lateral stability across the width of the belt while allowing axial flexibility. Stability is assured through the use of cushion stock that maintains cord integrity, assuring uniform distribution of load transmission. The fiber-loaded cogged construction provides optimum flexibility and minimizes heat build-up.

Classical Combo V-Belts

To resolve problem applications where belts are flipping over or jumping out of the sheaves, utilize Combo belts.

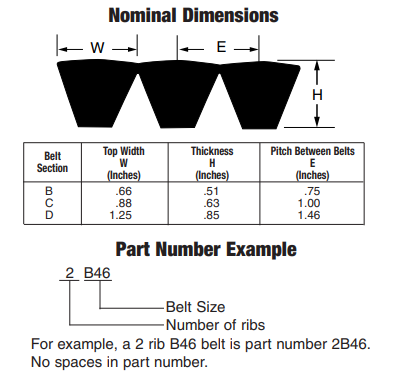

The tie band assures lateral rigidity and guides the belts into the sheave grooves. Nominal dimensions for B and C types are as described in the picture below

The tie band, reinforced with high strength transverse tensile cords, is fully oil and heat-resistant and permanently welds the individual belts together. Combos utilize premium quality belts, with all of their features and benefits. Assures equal load distribution in drives where high shock or pulsating loads cause belts to whip, flip over or jump out of the sheave grooves. Combos are ideal for use on vertical shaft drives.